|

MARCHANT (B) STANDARD

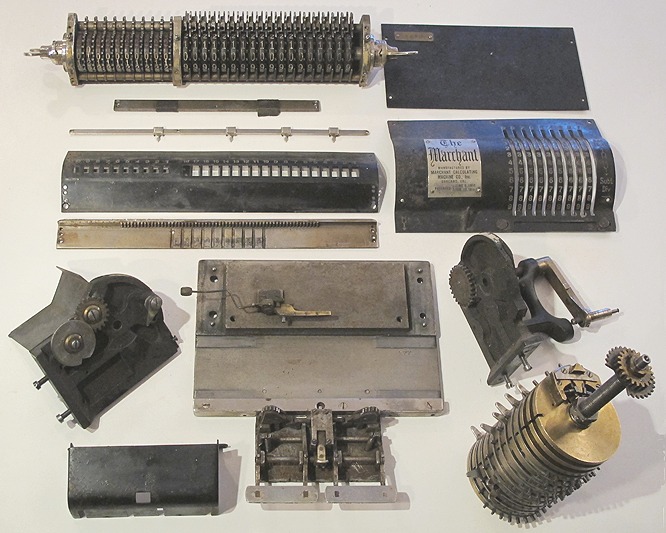

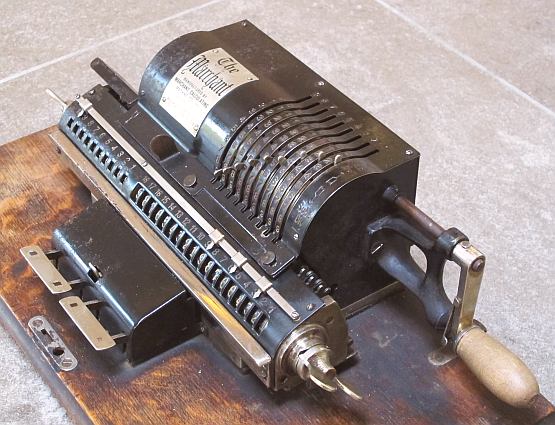

S N A P - S H O T S from the PROCESS of RESTORATION **************************************************** The disassembled machine after cleaning 90 years accumulated dirt ...  QUESTIONABLE is the over-complicated & over-sized STEPPING UNIT: The "Left-Step" was not precise positioning "into the slot". To fix: Different levers had to be bent back = Bad Engineering! ...  The AXLE of the CRANK and the DRIVING TOOTH-WHEEL was loose. To fix: Three holes were drilled on the perimeter and filled with hammered-in & glued-in nails to make a strong connection ...  The CRANK-HANDLE was missing. A new was made from a wooden handle. The "Pull-Out Mechanic" is made out of a pen-cap, washer & clip and glued inside; and a metal cap glued on its left side ...  The STEP-DRUM was blocked and had to be (1st) washed in gasoline and (2nd) applied with silicon oil for lubrication. Decision was made NOT TO RE-PAINT the machine!!! LET IT GO as the calculator was working in its last stage! FINALLY: See the MARCHANT (B) STANDARD from another angle ...  Back to the MARCHANT (B) STANDARD Main Page |

impressum: ************************************************************************** © C.HAMANN http://public.BHT-Berlin.de/hamann 11/13/12 |