VICTOR AUTOMATIC

( 10-Block-Keyboard / E-Model 75-85-54 )

A TRY TO RESTORATION ...

|

S N A P - S H O T S from the PROCESS of RESTORATION

****************************************************

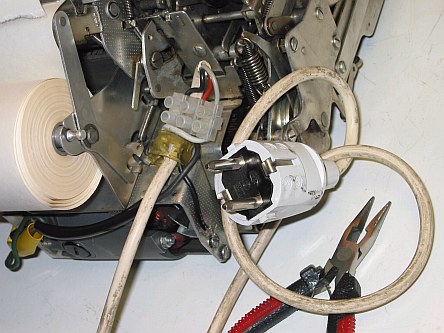

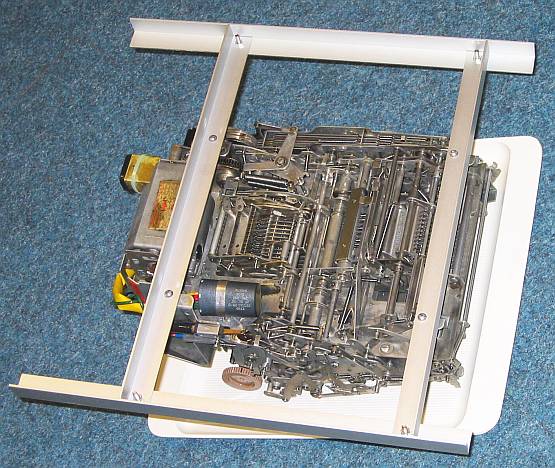

View into the open back side ...

... The machine came with a "quick & dirty fix" of the power cable.

( Probably the original cable or the plug or both were crumbled. )

A fixed cable is an obstacle in the process of restoration.

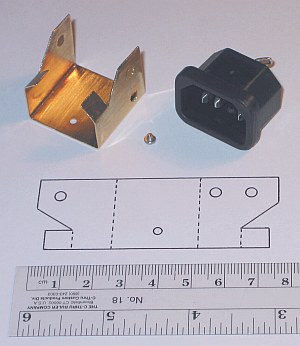

To install a MODERN PLUG, there is a HOLDER to construct first ...

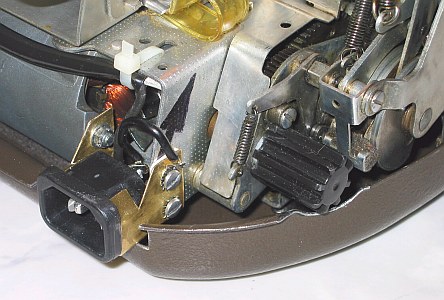

... Then the plug get fixed in the holder with component glue & screw

and mounted on the motor block with existing bolt, nut & screws ...

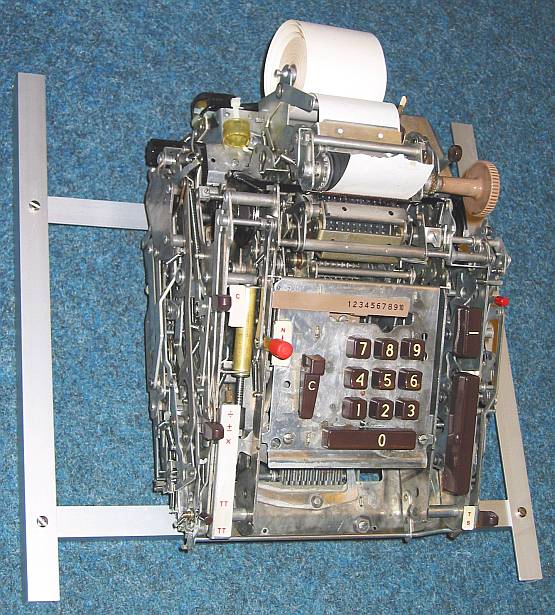

... The picture shows also:

A PLASTIC CAP WITH GRIPS is mounted on the motor axle. This is

necessary for MANUAL OPERATION of the machine to find out

their mal-functions. The base got a new cut-out for this cap

and the existing cut-out has to made broader for the new plug.

Also the COVER has to get a broader cut-out ...

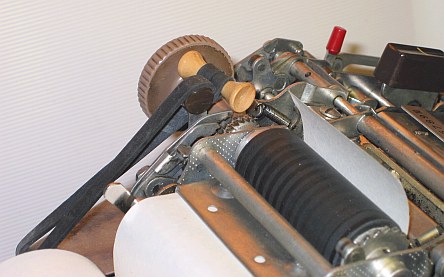

A T T E N T I O N

There is a "SAFETY BREAK" associated with the PAPER/RIBBON-LID.

To work with the open machine, the BROWN LEVER has to be hold down -

here with a BUNGEE CORD ...

To have access from all sides ( and to have space around all gears !)

the calculator is lifted (1st) with its own feet screws ...

... and (2nd) ...

... a frame was made for its support to have access

also from below - when placed between (e.g.) two chairs ...

Status at Xmas 2009: Machine is printing endless ZEROs.

There was a short time intervall when ADD/SUB was ok, but as

soon the MULT was tried, the machine fall back into ZERO looping.

...

In 2010 - together with a friend - we invested another day ...

... NO SUCCESS ...

SORRY - WE GAVE UP TRYING TO REPAIR THIS CHAOTIC HARDWARE !!!

( ... We will use it as a spare-part donator ... )

impressum: ************************************************************************** © C.HAMANN http://public.BHT-Berlin.de/hamann 09/24/10

One key was missing - A home-made RED is now the MAIN SELECTOR.

TECHNICAL DATA of the F u l l - Motorized Electro-Mechanical

********************************************************************

Printing-Calculator 10/11

Model: VICTOR 75-85-54 » AUTOMATIC «

Serial Number: 2360-612

Dimensions: (ca.) Width = 9_1/2 " / 24 cm

Depth = 14_1/4 " / 36 cm

Height = 7_1/2 " / 19 cm

Weight: (ca.) 23 lbs / 10.5 kg

Power Supply: 220 V AC / DC 80 W grounded

Mechanics: Serial-to-parallel Conversion,

One key was missing - A home-made RED is now the MAIN SELECTOR.

TECHNICAL DATA of the F u l l - Motorized Electro-Mechanical

********************************************************************

Printing-Calculator 10/11

Model: VICTOR 75-85-54 » AUTOMATIC «

Serial Number: 2360-612

Dimensions: (ca.) Width = 9_1/2 " / 24 cm

Depth = 14_1/4 " / 36 cm

Height = 7_1/2 " / 19 cm

Weight: (ca.) 23 lbs / 10.5 kg

Power Supply: 220 V AC / DC 80 W grounded

Mechanics: Serial-to-parallel Conversion,