It is now = 10:34 in SanFrancisco

= 19:34 in Berlin

W O R L D T I M E C L O C K » K U N D O « (1960)

******************************************************************

( 23 cm Diameter ) Kieninger & Obergfell, St.Georgen / Germany

The world map is shown in "North Polar Projection". GMT is on the

bottom. This "tic-tac" clock has a "balanced spring" mechanic.

A battery powered motor winds up the main spring every 4 minutes

due to a MECHANICAL(!) TIMER. A 12 HOUR FACE shows the LOCAL TIME.

The outer ring with 24 HOURS shows the TIME-ZONES & WORLD CITIES

with DAY & NIGHT.

R E M A R K S :

==================================================================

(A) HOW THE ELECTRO-MECHANICAL K U N D O WORLD CLOCK WORKS:

---------------------------------------------------------------

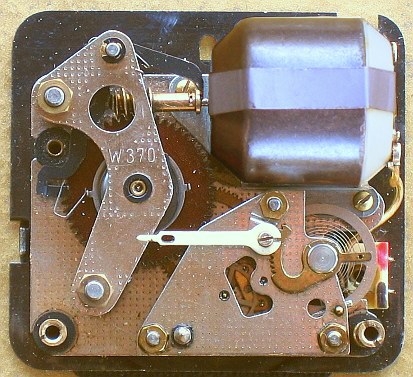

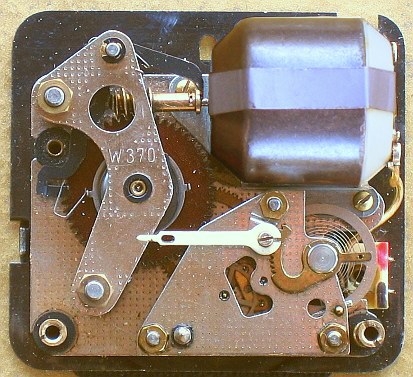

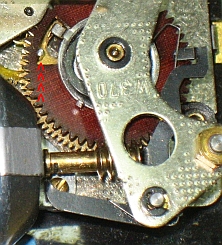

View without plastic cover / battery holder ...

The red/black marks on the right side indicates where the contacts

of the battery are connected when the cover is mounted. From there

cables with clips go direct to the motor. The On/Off-Switch is

INSIDE (!) THE MOTOR. On the Motor-Axle is a HELIX-Gear mounted.

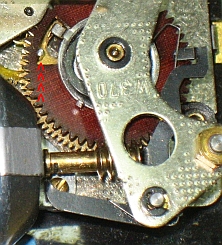

This HELIX drives the PLASTIC-Gear. On its Axle below (s.pic.right)

is the SPRING and a BRASS-Gear, what drives the clock-work.

HOW IT WORKS (s.Pic.left): Inside the PLASTIC-Gear is a RING with a

"Nose-DOWN" through a "Cut-Out" and a PAIR "Noses-UP" on top. From

the BRASS-Gear a ROD (s.>>>> MARK !) pushes the "Nose-DOWN" to the

end of the "Cut-Out"... moves the PLASTIC-Gear... HELIX... Motor-

Axle... Power-ON... Motor ON: The Clock-Spring gets wind. Important

Detail: The "Black-L-LEVER" has a SPRING on its end, touching the

PLASTIC-Gear on a "Nose-UP", building-up TENSION... When released,

the L-LEVER push HELIX... Motor get power, turns and "over-shoot"

until the PLASTIC-Gear stop and the Motor-Axle will return to idle

(=OFF)Position. This assembly works as a MECHANICAL-TIMER.

The red/black marks on the right side indicates where the contacts

of the battery are connected when the cover is mounted. From there

cables with clips go direct to the motor. The On/Off-Switch is

INSIDE (!) THE MOTOR. On the Motor-Axle is a HELIX-Gear mounted.

This HELIX drives the PLASTIC-Gear. On its Axle below (s.pic.right)

is the SPRING and a BRASS-Gear, what drives the clock-work.

HOW IT WORKS (s.Pic.left): Inside the PLASTIC-Gear is a RING with a

"Nose-DOWN" through a "Cut-Out" and a PAIR "Noses-UP" on top. From

the BRASS-Gear a ROD (s.>>>> MARK !) pushes the "Nose-DOWN" to the

end of the "Cut-Out"... moves the PLASTIC-Gear... HELIX... Motor-

Axle... Power-ON... Motor ON: The Clock-Spring gets wind. Important

Detail: The "Black-L-LEVER" has a SPRING on its end, touching the

PLASTIC-Gear on a "Nose-UP", building-up TENSION... When released,

the L-LEVER push HELIX... Motor get power, turns and "over-shoot"

until the PLASTIC-Gear stop and the Motor-Axle will return to idle

(=OFF)Position. This assembly works as a MECHANICAL-TIMER.

(B) REPAIR / RESTORATION:

-------------------------

(1)

Nothing worked - also not after oiling and cleaning contacts ...

(2)

To open the motor a little force was necessary - and 2 hidden

pins, holding the axle/contact plate, cracked its plastic. Now

the V-shaped inner contacts where visible and obvious unable to

touch the collector of the motor. Shaped it right with trial-and-

error: They have to give contact when the axle is in its right

position, and out of contact otherwise. 2 CLIPS, made out of CAT

FOOD CAN ( fixed with tape ), holding in place the plastic plate

on the cast metal motor housing.

(3)

The helix-gear was loose and needed a new connection: On the

motor axle is a one-turn spring mounted and through the slot of

the helix-gear fixed. The exact position of the helix-gear on the

axle is part of the fine-tuning procedure ...

(4)

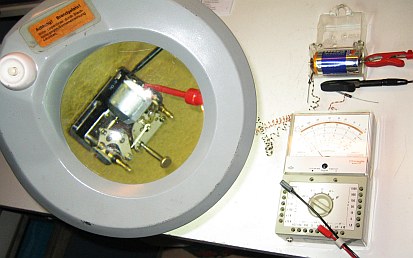

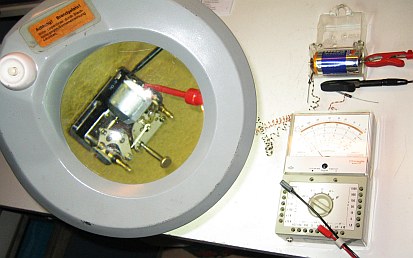

The Tuning-Procedure had to be made with an AmpMeter "In-the-Loop"

to make sure, that the Motor-On/Off is working perfect. To make the

»KUNDO« working again is difficult (+ time-consuming) because many

parameters have to be adjust "right" at the same time ...

(B) REPAIR / RESTORATION:

-------------------------

(1)

Nothing worked - also not after oiling and cleaning contacts ...

(2)

To open the motor a little force was necessary - and 2 hidden

pins, holding the axle/contact plate, cracked its plastic. Now

the V-shaped inner contacts where visible and obvious unable to

touch the collector of the motor. Shaped it right with trial-and-

error: They have to give contact when the axle is in its right

position, and out of contact otherwise. 2 CLIPS, made out of CAT

FOOD CAN ( fixed with tape ), holding in place the plastic plate

on the cast metal motor housing.

(3)

The helix-gear was loose and needed a new connection: On the

motor axle is a one-turn spring mounted and through the slot of

the helix-gear fixed. The exact position of the helix-gear on the

axle is part of the fine-tuning procedure ...

(4)

The Tuning-Procedure had to be made with an AmpMeter "In-the-Loop"

to make sure, that the Motor-On/Off is working perfect. To make the

»KUNDO« working again is difficult (+ time-consuming) because many

parameters have to be adjust "right" at the same time ...

powered by a 1.5 Volt D-Cell

impressum:

******************************************************************

© C.HAMANN http://public.BHT-Berlin.de/hamann 12/14/14

powered by a 1.5 Volt D-Cell

impressum:

******************************************************************

© C.HAMANN http://public.BHT-Berlin.de/hamann 12/14/14

|

The red/black marks on the right side indicates where the contacts

of the battery are connected when the cover is mounted. From there

cables with clips go direct to the motor. The On/Off-Switch is

INSIDE (!) THE MOTOR. On the Motor-Axle is a HELIX-Gear mounted.

This HELIX drives the PLASTIC-Gear. On its Axle below (s.pic.right)

is the SPRING and a BRASS-Gear, what drives the clock-work.

HOW IT WORKS (s.Pic.left): Inside the PLASTIC-Gear is a RING with a

"Nose-DOWN" through a "Cut-Out" and a PAIR "Noses-UP" on top. From

the BRASS-Gear a ROD (s.>>>> MARK !) pushes the "Nose-DOWN" to the

end of the "Cut-Out"... moves the PLASTIC-Gear... HELIX... Motor-

Axle... Power-ON... Motor ON: The Clock-Spring gets wind. Important

Detail: The "Black-L-LEVER" has a SPRING on its end, touching the

PLASTIC-Gear on a "Nose-UP", building-up TENSION... When released,

the L-LEVER push HELIX... Motor get power, turns and "over-shoot"

until the PLASTIC-Gear stop and the Motor-Axle will return to idle

(=OFF)Position. This assembly works as a MECHANICAL-TIMER.

The red/black marks on the right side indicates where the contacts

of the battery are connected when the cover is mounted. From there

cables with clips go direct to the motor. The On/Off-Switch is

INSIDE (!) THE MOTOR. On the Motor-Axle is a HELIX-Gear mounted.

This HELIX drives the PLASTIC-Gear. On its Axle below (s.pic.right)

is the SPRING and a BRASS-Gear, what drives the clock-work.

HOW IT WORKS (s.Pic.left): Inside the PLASTIC-Gear is a RING with a

"Nose-DOWN" through a "Cut-Out" and a PAIR "Noses-UP" on top. From

the BRASS-Gear a ROD (s.>>>> MARK !) pushes the "Nose-DOWN" to the

end of the "Cut-Out"... moves the PLASTIC-Gear... HELIX... Motor-

Axle... Power-ON... Motor ON: The Clock-Spring gets wind. Important

Detail: The "Black-L-LEVER" has a SPRING on its end, touching the

PLASTIC-Gear on a "Nose-UP", building-up TENSION... When released,

the L-LEVER push HELIX... Motor get power, turns and "over-shoot"

until the PLASTIC-Gear stop and the Motor-Axle will return to idle

(=OFF)Position. This assembly works as a MECHANICAL-TIMER.

(B) REPAIR / RESTORATION:

-------------------------

(1)

Nothing worked - also not after oiling and cleaning contacts ...

(2)

To open the motor a little force was necessary - and 2 hidden

pins, holding the axle/contact plate, cracked its plastic. Now

the V-shaped inner contacts where visible and obvious unable to

touch the collector of the motor. Shaped it right with trial-and-

error: They have to give contact when the axle is in its right

position, and out of contact otherwise. 2 CLIPS, made out of CAT

FOOD CAN ( fixed with tape ), holding in place the plastic plate

on the cast metal motor housing.

(3)

The helix-gear was loose and needed a new connection: On the

motor axle is a one-turn spring mounted and through the slot of

the helix-gear fixed. The exact position of the helix-gear on the

axle is part of the fine-tuning procedure ...

(4)

The Tuning-Procedure had to be made with an AmpMeter "In-the-Loop"

to make sure, that the Motor-On/Off is working perfect. To make the

»KUNDO« working again is difficult (+ time-consuming) because many

parameters have to be adjust "right" at the same time ...

(B) REPAIR / RESTORATION:

-------------------------

(1)

Nothing worked - also not after oiling and cleaning contacts ...

(2)

To open the motor a little force was necessary - and 2 hidden

pins, holding the axle/contact plate, cracked its plastic. Now

the V-shaped inner contacts where visible and obvious unable to

touch the collector of the motor. Shaped it right with trial-and-

error: They have to give contact when the axle is in its right

position, and out of contact otherwise. 2 CLIPS, made out of CAT

FOOD CAN ( fixed with tape ), holding in place the plastic plate

on the cast metal motor housing.

(3)

The helix-gear was loose and needed a new connection: On the

motor axle is a one-turn spring mounted and through the slot of

the helix-gear fixed. The exact position of the helix-gear on the

axle is part of the fine-tuning procedure ...

(4)

The Tuning-Procedure had to be made with an AmpMeter "In-the-Loop"

to make sure, that the Motor-On/Off is working perfect. To make the

»KUNDO« working again is difficult (+ time-consuming) because many

parameters have to be adjust "right" at the same time ...

powered by a 1.5 Volt D-Cell

powered by a 1.5 Volt D-Cell